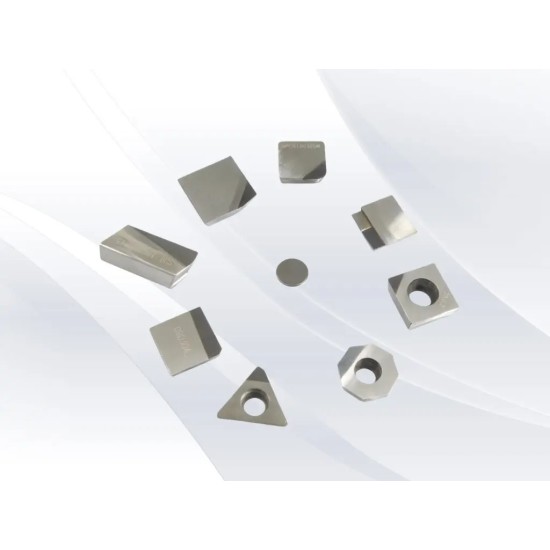

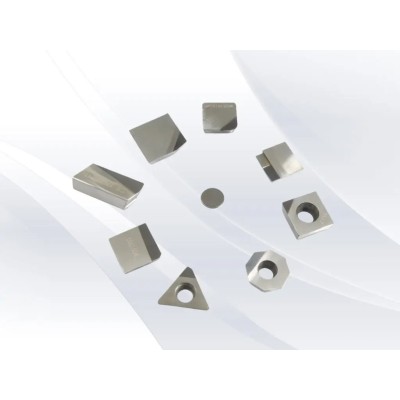

Detailed Description

PCBN/PCD Indexable Milling Inserts utilize advanced super-hard materials and precision geometric design. Optimized edge preparation technology and rational chip breaker geometries ensure exceptional stability during high-speed milling. PCBN inserts are specifically designed for difficult-to-machine materials like hardened steel and cast iron, offering excellent red hardness and wear resistance. PCD inserts target non-ferrous metals such as high-silicon aluminum alloys and composite materials, capable of achieving high surface quality machining. Precise locating structures and a reliable clamping system ensure insert indexing accuracy, providing users with an efficient, precise, and economical milling solution.

Features

● Super-hard Wear-resistant Material: PCBN/PCD materials provide exceptional wear resistance and thermal stability, offering significantly longer tool life compared to traditional carbide.

● Precision Geometric Design: Optimized edge preparation and chip breaker geometry ensure stable cutting and form short chips, resulting in excellent surface quality and laying the foundation for unmanned workshops.

● High Efficiency and Cost-effectiveness: Multi-cutting edge design and quick indexing function greatly reduce cost per edge and improve machining efficiency.

● Stable Machining Performance: Precise locating structure and clamping system guarantee repeatable insert positioning accuracy, enhancing machining consistency.