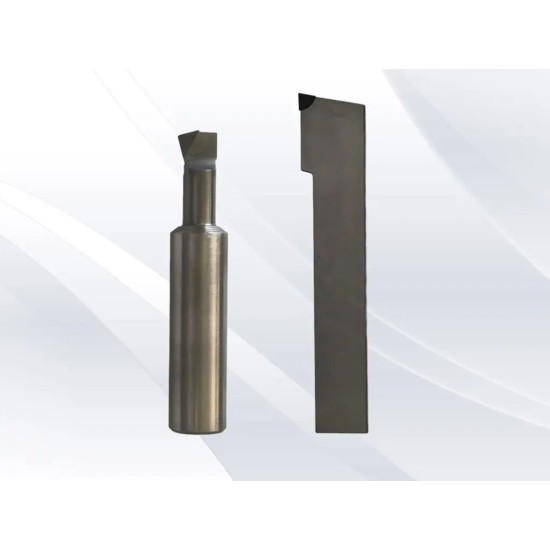

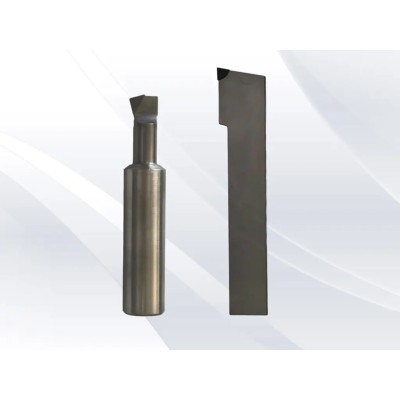

Detailed Description

PCBN brazed turning tools feature a negative rake angle design with reinforced cutting edges, delivering excellent impact resistance. They are suitable for medium-to-low speed heavy-duty cutting and intermittent machining of materials like hardened steel (above HRC45) and wear-resistant cast iron. These tools significantly improve machining efficiency and surface consistency, serving as an economical and optimal solution to replace traditional grinding processes. They are particularly suitable for gear machining in automotive transmissions.

Features

● Robust Edge Structure: The negative rake angle combined with an S-type reinforced edge design provides exceptional chipping resistance, making it ideal for intermittent cutting and heavy-duty conditions.

● Excellent Thermal Stability: PCBN material exhibits outstanding high-temperature resistance and red hardness, with minimal performance degradation during continuous cutting.

● Superior Wear Resistance: High CBN content ensures extremely low wear even under high temperatures and pressure, with a lifespan far exceeding that of carbide tools.

● Significant Process Benefits: Supports "turning instead of grinding," eliminating the grinding process, shortening production cycles, and reducing per-unit costs.

● PCD tools are suitable for high-speed, high-efficiency, and high-stability machining of non-ferrous metals.