The injection molding products produced by its molds can ensure the surface finish and the assembly effect of home appliances.

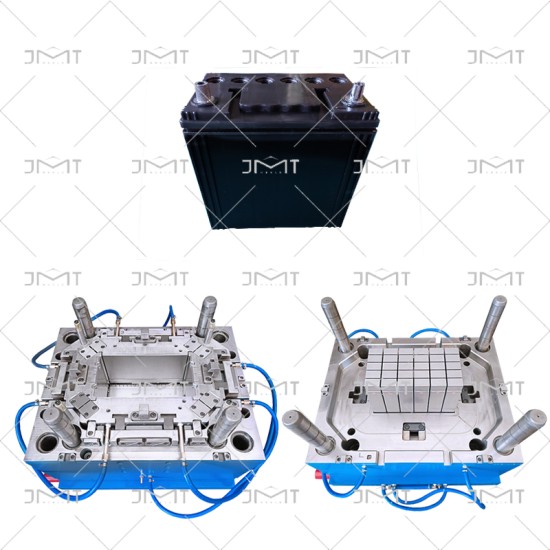

| Plastic resin | PP/PE |

| Mould dimension (mm) | 600*520*730 |

| Mould weight (T) | 1.5T |

| Injection machine Ton | 5300T |

| Mould cavity steel | 718H |

| Mould core steel | H13 |

| Gate system | 7 tips YUDO hot runner |

| Mould life | 1M |

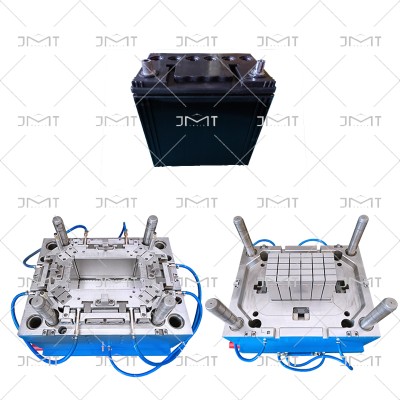

When designing and manufacturing a battery box mold, there are several key points to consider to ensure that the mold performs well, produces high-quality parts, and meets the desired specifications. Here are the key points to focus on:

Steel selection

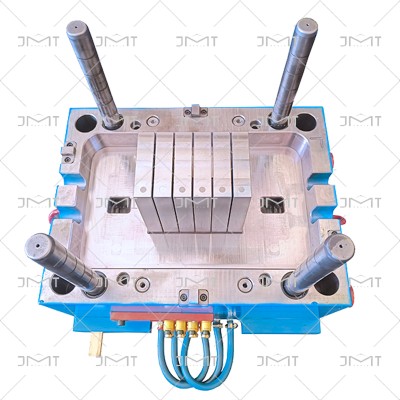

Mold design

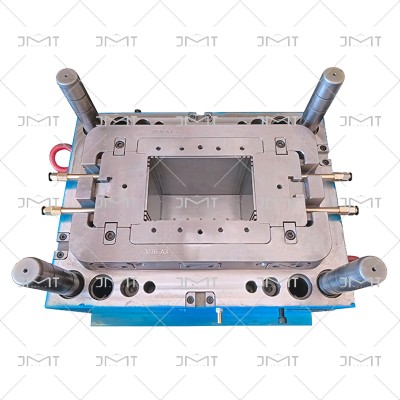

Cooling system

Venting

Tolerance and fitting

Durability of mold

Easy of assembly and disassembly

For JMT battery box molds, we will carefully consider dimension tolerances, choosing best steel and proceed heat treatment. Damageable parts will be made with inserts. Position of terminals and magic eyes will be inserted as well, to ensure customer can change inserts easily.