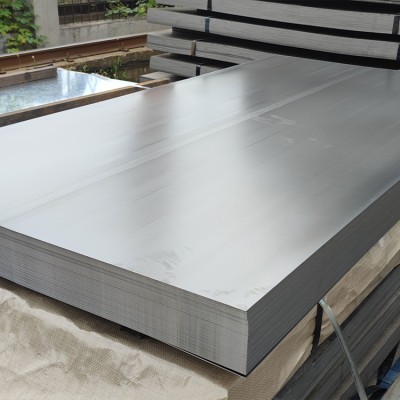

Product description

Cold-rolled steel is a steel plate obtained by rolling a hot-rolled steel coil and further thinning the No. 1 steel plate to a target thickness under cold rolling conditions at room temperature. Its production process is precisely controlled to obtain iron-based alloys of a certain thickness, width and surface quality.

Cold rolled steel has higher strength and hardness than hot rolled steel and is easier to shape. This is because cold-rolled steel undergoes more processing deformation during the manufacturing process, and the grain size is smaller, forming a more uniform and dense structure.

Because cold-rolled raw coils are relatively brittle and hard and not suitable for processing, cold-rolled steel plates are usually required to be annealed, pickled and surface smooth before being handed over to customers.

The maximum thickness of cold rolling is 0.1–8.0MM or less. For example, the thickness of cold-rolled steel plates in most factories is less than 4.5MM. The minimum thickness and width are determined according to the equipment capabilities and market demand of each factory.

Product parameter table

| Grade | Q195,Q215,Q235,08AL,SPCC,SPCD,SPCE,SPCEN,ST12,ST13,ST14,ST15,ST16,DC01,DC03,DC04,DC05,DC06 |

| Standard | ISO,JIS,ASTM,AS EN |

| Mechnical | Commercial / Drawing / Deep Drawing /Extra Deep Drawing/Structural quality |

| Surface treatment | Chromated and oiled, and ant-ifinger |

| Hardness | Softy, half hard ,hard quality |

| Thickness | 0.12-6.0mm |

| Width | 600-1500mm |

| Coil weight | 3-8MT/Coil or as your request |

| MOQ | 5MT |

| Packaging | Export standard, seaworthy |