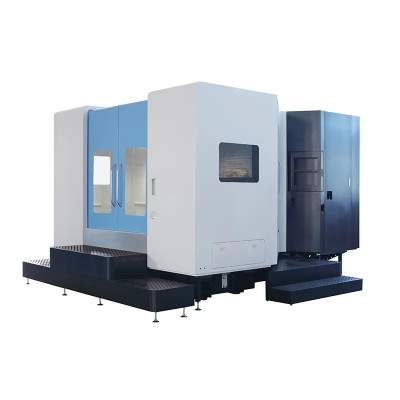

Normal Speed Cut-To-Length Line

WUXI MAZS MACHINERY SCIENCE & TECHNOLOIGY CO.,LTD

metal coil cold rolling mill lines, slitting lines, HF welded pipe mill lines, cut-to-length lines, roll forming machines

metal coil cold rolling mill lines, slitting lines, HF welded pipe mill lines, cut-to-length lines, roll forming machines

Introduction:

Normal-speed cut-to-length line (sheet CTL line) can meet customer's request of max line speed 40m/min by uncoiling & leveling a coil strip, and then shearing the leveled flat strip to certain length of sheets.

The sheet cut-to-length line has one leveling machine driven by DC or AC motor, and the length-fixing is by encoder.

The Normal speed sheet cut-to-length line (sheet CTL line) fit steel coils with thickness: (0.2-2mm, 0.3-3mm, 0.6-4mm) and changeable width and length of finished sheets depend on customer's practical need.

Advantages and Characteristics of Sheet CTL Line:

1. Fast speed and high precision

Line speed can be up to 40m/min, 7-8pcs/min 2000mm Length sheets in average.

Leveling precision: ±1mm/㎡

Sheet length precision: ±0.5mm/m

Sheet diagonal length precision: ±0.5mm/m

2. Thin coils differ in coil weight, when max coil weight is small, usually single mandrel (cantilever) uncoiler for this sheet cut-to-length line (sheet CTL line) is adopted.

3. To make flat steel sheets, the diameter of leveling rollers should be scientifically proper, we confirm diameter of leveling rollers by actual experiences and engineering calculation.

4. Automatically piling-up bracket can receive finished sheets and automatically pile them up orderly.

5. Hole accumulator between decoiling and leveling, is necessary to protect sheet surface and make sure the simultaneously work of decoiling and leveling.

| The Company | WUXI MAZS MACHINERY SCIENCE & TECHNOLOIGY CO.,LTD |

| The contact | Mazs |

| The Address | |

| The Website | https://wmmworld.co/com/mazs/ |

Response Rate: High

Avg Response Time: 24–48 h

Business Type:Manufacturers , Traders