Product Description

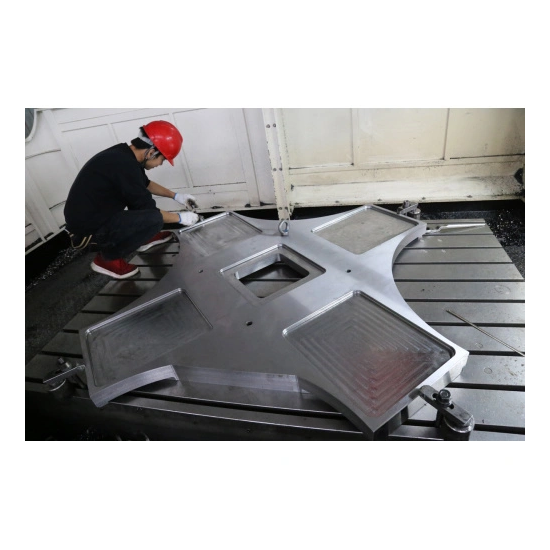

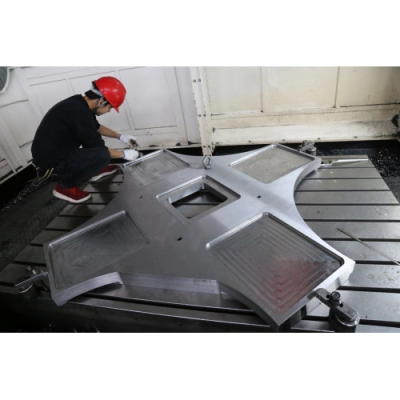

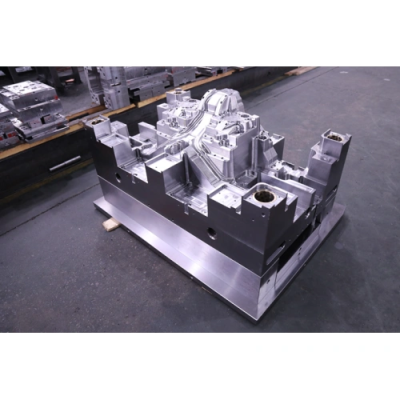

Mechanical Plate Parts Processing offers precision manufacturing services for custom-engineered plate components used across industrial and technological sectors. Utilizing advanced CNC machining, laser cutting, and forming technologies, we deliver high-accuracy plate parts with strict adherence to design specifications, ensuring reliability in critical mechanical systems.

Applications

Automotive: Chassis brackets, engine mounts, and structural reinforcements.

Industrial Machinery: Gears, bearing plates, and machine frames.

Aerospace: Heat shields, mounting panels, and actuator components.

Electronics: Enclosures, heat sinks, and mounting plates.

Construction: Steel connectors, brackets, and support beams.

Key Features & Technical Specifications

Materials: Stainless steel, aluminum (e.g., 6061, 5052), carbon steel, titanium.

Thickness Range: 0.5mm to 50mm (customizable).

Dimensional Tolerance: ±0.05mm to ±0.1mm (depending on complexity).

Surface Finish: Options include anodizing, powder coating, plating, or grinding (Ra ≤ 1.6μm).

Max. Plate Size: Up to 3000mm × 1500mm.

Processing Techniques: CNC milling, laser/plasma cutting, punching, bending (±0.5° angular accuracy).

Production Capacity: Prototyping to high-volume batches (lead times as low as 5 days).

Compliance & Industry Standards

Quality Management: ISO 9001:2015 certified.

Material Standards: ASTM A36, DIN 1.4301 (stainless steel), AMS 4027 (aluminum).

Sector-Specific Certifications: IATF 16949 (automotive), AS9100D (aerospace).

Quality control

Systematic quality control: SG DIE SET has been implementing the whole life cycle quality control from raw materials, processing, finished product packaging and storage, and after-sales products.

Service commitment

It is our purpose to serve every customer wholeheartedly;

Reply within 2 hours after receiving the complaint, and give a solution within 24 hours;