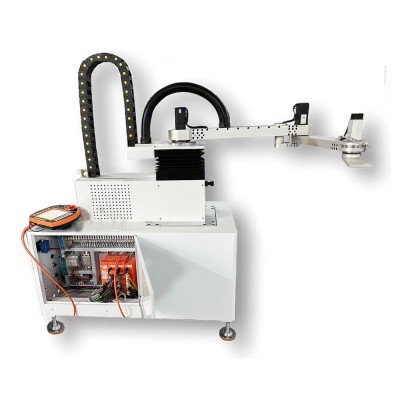

Infrared Picosecond Single-Platform Glass Laser Cutting Equipment

Demark (Wuhan) Technology Co.,Ltd

laser cutting machine, laser welding machine, laser cleaning machine and laser surface treatment equipment.

laser cutting machine, laser welding machine, laser cleaning machine and laser surface treatment equipment.

This equipment adopts infrared picosecond laser technology and is designed for cutting and processing all kinds of hard and brittle materials. With a platform size of 500×600mm, cutting thickness of 0.03-20mm, and maximum cutting speed of 1000mm/s, it can accurately complete the shape and inner hole processing of ordinary glass, optical glass, quartz, and other materials. The cutting edge has no taper, and the chipping is <0.01mm. It is characterized by high speed, precision, and environmental protection, and is an efficient solution for laser cutting of hard and brittle materials.

Product Features

Precision Cutting with Picosecond Laser, Excellent Edge Quality

Adopting infrared picosecond laser technology, the cutting edge has no taper and chipping is <0.01mm, meeting the high-precision processing requirements of optical glass, quartz, etc. It completely solves the edge defects of traditional cutting, perfectly matching the core requirement of glass laser cutting for precision.

Full Coverage of Hard and Brittle Materials, Strong Scene Adaptability

It can process various hard and brittle materials such as ordinary glass, optical glass, quartz, sapphire, and tempered glass. It supports shape processing and inner hole cutting. The platform size of 500×600mm is suitable for workpieces of multiple specifications, realizing efficient production of "one machine for multiple materials".

High-Speed Processing + Low-Cost Operation and Maintenance, Outstanding Production Efficiency

With a maximum cutting speed of 1000mm/s, it leads in the processing efficiency of special-shaped workpieces. There are no consumables, waste liquid, or waste water, resulting in low operation and maintenance costs and high yield, greatly improving the production economy of laser cutting.

Convenient Operation, Environmental Protection and Safety

Various specifications of products can be switched seamlessly, and the operation is simple and easy to use. The processing process produces no waste residue, waste liquid, or waste water, and does not scratch the product surface, complying with environmental production standards and reducing the environmental management cost of the workshop.

| The Company | Demark (Wuhan) Technology Co.,Ltd |

| The contact | demark |

| The Address | |

| The Website | https://wmmworld.co/com/demark/ |

Infrared Picosecond Single-Platform Glass Laser Cutting Equipment

Response Rate: High

Avg Response Time: 24–48 h

Business Type:Manufacturers , Traders