An Electric Meter Box Mould is a specialized mold used to manufacture durable and strong enclosures for electric meters, ensuring precise design and functionality.

| Plastic resin | PC/ABS |

| Mould dimension (mm) | 890*570*700 |

| Mould weight (T) | 5500 KG |

| Injection machine Ton | 350T |

| Mould cavity steel | Chinese 718H |

| Mould core steel | Chinese 718H |

| Gate system | 2 tips YUDO hot runner open gate |

| Mould life | 300,000 shots |

Introduction

Achieving precision and high quality is at the heart of any injection molding process, especially when the product involves intricate details. This case exemplifies JMT’s commitment to quality, precision, and timely delivery. The project faced numerous challenges in manufacturing the plastic crate mould, but JMT overcame these hurdles by employing innovative solutions, ensuring the final product met the highest standards.

Achieving Customer’s Request

The customer required a plastic crate mould that would produce highly durable and precisely shaped crates, with an efficient production process and minimal defects. JMT worked closely with the customer to understand their specific requirements and used advanced technologies and processes to meet these needs, ensuring both functional and aesthetic expectations were fulfilled.

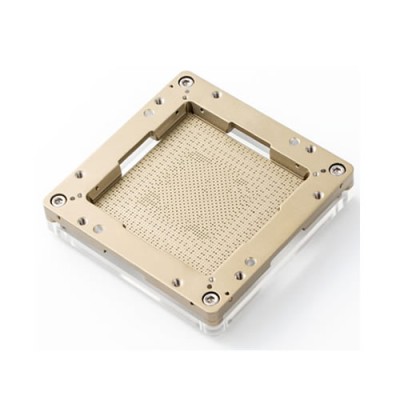

Mold Description

The plastic crate mould features a complex design that requires high precision in every component. The mould is designed to accommodate detailed features such as stacking capabilities and structural reinforcements, which are essential for the crate’s durability and functionality in the logistics and storage industry.

Mold Design

The design of the plastic crate mould focuses on both beauty and practicality. By carefully selecting materials and designing for optimal flow and cooling efficiency, JMT created a mould that ensures consistent, high-quality production while being easy to maintain and operate, providing both aesthetic appeal and functional utility.

Mold Flow Analysis

Using mold flow analysis, JMT predicted potential defects such as uneven filling or air traps before production even began. By addressing these issues early in the design phase, the team optimized the mould to prevent common injection molding problems, ensuring the final product met the customer’s specifications with minimal defects.

Mold Machining

With the help of state-of-the-art machinery such as CNC and EDM, JMT is able to manufacture the plastic crate mould with exceptional precision. Every detail is meticulously crafted to ensure that each part fits perfectly, with the latest machines playing a pivotal role in creating moulds that exceed industry standards for quality.

Quality Control

JMT’s commitment to quality control is evident in its use of CMM inspections to validate the mould’s accuracy. Each detail, contour, and dimension is carefully checked to ensure the product aligns with the company’s high standards. Additional quality control tools are also employed to guarantee the mould and the final plastic crates meet both the customer’s and industry’s stringent requirements.

Difficulty Solutions

During the production of the plastic crate mould, JMT encountered challenges such as ensuring uniform cooling and preventing warping during injection. Through innovative solutions such as advanced cooling channel design and precise machining, these difficulties were overcome, resulting in a mould that produces high-quality crates without defects.

Conclusion

JMT’s approach to creating the plastic crate mould encompassed a comprehensive strategy of high manufacturing precision, extended service life, shortened production cycles, and optimized production costs. This approach not only met but exceeded customer and industry expectations, showcasing JMT’s dedication to excellence in every aspect of the mould manufacturing process.

| The Company | Taizhou Huangyan JMT Mould CO.,LTD |

| The contact | jennifer |

| The Address | |

| The Website | https://wmmworld.co/com/jmtmould/ |

Response Rate: High

Avg Response Time: 24–48 h

Business Type:Manufacturers , Traders