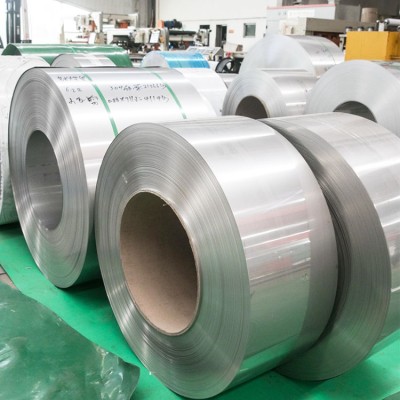

Stainless Steel Coil

SHANDONG YUNSHAN METAL MANUFACTURING CO,LTD

carbon steel, Stainless Steel, Aluminum and Galvanized

carbon steel, Stainless Steel, Aluminum and Galvanized

Stainless steel coils are divided into austenite, ferrite, martensite, dual-phase (ferrite-austenite) stainless steel cold-rolled coils and stainless steel hot-rolled coils.

Executive standards: GB/T4238, ASTM/ASME, JIS G4305, EN10088, BSEN10028, GB/T3280, GB/T4237

Specifications:

Stainless steel coils are widely used in chemical, food, medicine, paper, petroleum, atomic energy and other industries, as well as various parts and components of construction, kitchen utensils, tableware, vehicles, and household appliances.

Material GRADE: 201 202 301 304 304L 316 316L

| Standard | ASME, ASTM, EN, BS, GB, DIN, JIS, etc |

| Technique | Hot rolled / cold rolled |

| Width | 10mm-1250 mm |

| Thickness | 0.1mm-3.0mm |

| Surface | 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, checkered, embossed, hair line, sand blast, Brush, etching, etc |

| Packaging | Standard export sea-worthy packing |

| Finish | Cold rolled coil (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated) |

| Surface Finish | Definition | Application |

|---|---|---|

| 2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

| BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

| NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

| NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

| HL | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building Construction. |

| NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

Note: All specifications and standards are subject to change without prior notice. Please contact us for the most up-to-date information.

| The Company | SHANDONG YUNSHAN METAL MANUFACTURING CO,LTD |

| The contact | yunshan |

| The Address | |

| The Website | https://wmmworld.co/com/yunshan/ |

Response Rate: High

Avg Response Time: 24–48 h

Business Type:Manufacturers , Traders