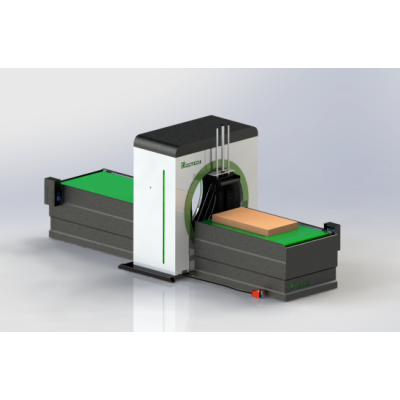

Waste conveying system

Small finished products or residues after cutting can be transported to the front side through the conveying system placed at the bottom of the bed, saving labor costs.

With the front-end collecting device, it is easy to collect and save time.

1. This single-platform laser cutting machine combines intelligence, efficiency, and practicality. It adopts an integrated design concept, features a small footprint, and is widely applicable, offering intelligent processing and stable cutting.

2. The machine bed structure is fully upgraded—heavy-duty steel plates are welded with mortise and tenon rivets, and then annealed for fine processing. This provides enhanced rigidity and vibration resistance, strong load-bearing capacity, and no deformation during use, ensuring smooth operation at high speeds.

3. Utilizing a Raytools small-core laser, high beam quality and highly concentrated energy improves efficiency while significantly enhancing cutting accuracy, especially when cutting circular arcs and complex workpieces.

4. Utilizing new fire-resistant, heat-insulating technology, this machine effectively reduces thermal deformation during processing and extends its service life.

5. The servo motor, reducer, and rack are all from renowned brands, ensuring high quality, high machine precision, and a guaranteed service life.

6. The intelligent operating system is easy to learn and reduces operator requirements. It is compatible with various drawing, output, and management software, ensuring efficient coordination. The machine control algorithm is continuously optimized to improve cutting efficiency and reduce processing energy consumption. 7. The integrated waste conveying platform automatically collects and conveys waste while completing precise cutting, significantly improving workshop cleanliness and production efficiency, and achieving an intelligent closed-loop production system.

8. A wide range of power options, from 3,000 to 12,000W, are available. The powerful power configuration and optimized cutting process make it easy to process a wide range of materials.

9. The high-performance aluminum profile crossbeam is extremely lightweight, achieving ultra-high dynamic performance and effectively absorbing and damping vibrations generated by equipment operation.

10. Widely used in industries such as chassis and cabinets, sheet metal processing, billboards, and elevator manufacturing.

Fiber laser cutting machine RCL4020-3K with Waste conveying system Warranty & Support

As the global leader in CNC laser cutting technology, Roclas-laser.com guarantees:

1-year limited warranty covering the entire machine (consumables excluded).

Lifetime maintenance support with 24/7 English-speaking customer service.

Free replacement parts for non-artificial damages during the warranty period.

Post-warranty repairs at cost price—only actual service fees apply.

Certifications: Compliant with CE, FDA, and SGS standards.

Fiber laser cutting machine RCL4020-3K with Waste conveying system FAQs: Request a Free Quote

To receive a tailored quotation, kindly provide the following details via email:

Material Type: Do you cut metal sheets/plates, pipes/tubes, or both?

Tube Specifications (if applicable): Maximum length, diameter, and thickness.

Sheet Cutting Requirements: Desired maximum working area.

End Use: What applications will the processed materials serve?

Nearest Seaport: For shipping logistics.

Experience Level: Any prior laser cutting expertise?

Preferred Contact Method: Skype, WhatsApp, etc.

Buyer Type: End user or reseller

Fiber laser cutting machine RCL4020-3K with Waste conveying system Cost & Pricing Factors

The total investment in a fiber laser cutter depends on multiple variables:

Hardware: Machine components, laser power (1500W–60,000W), and add-ons.

Software: Controller system capabilities.

Logistics: Shipping, taxes, and customs duties.

Support: After-sales service and technical assistance.

Manufacturer Reputation: Opt for a certified supplier with proven expertise.

Performance Metrics: Ensure high speed, precision, and material compatibility.

After-Sales Commitment: Verify prompt technical support and troubleshooting.

| The Company | ROCLAS® MACHINERY CO.,LTD |

| The contact | roclas |

| The Address | |

| The Website | https://wmmworld.co/com/roclas/ |

Fiber laser cutting machine RCL4020-3K with Waste conveying system

Response Rate: High

Avg Response Time: 24–48 h

Business Type:Manufacturers , Traders