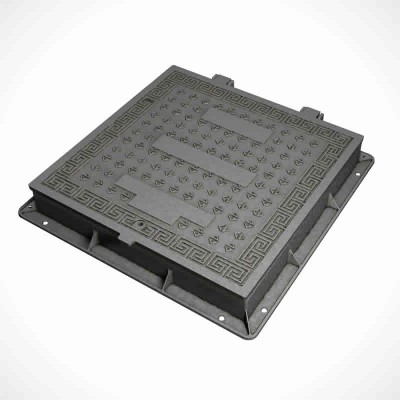

This mold is engineered for manufacturing heavy-duty plastic pallets with high-load capacity and exceptional durability. By integrating reinforced rib structures and anti-slip surfaces, the injection-molded pallets ensure stable stacking and safe transportation in logistics and warehousing. The mold’s modular design allows customization of pallet sizes and configurations, while high-wear-resistant steel ensures a lifespan exceeding 500,000 cycles.

Introduction

Precision and quality are the heart of any injection molding process, especially for products with complex details. This case demonstrates JMT’s commitment to quality, accuracy, and on-time delivery. The project faced challenges typical of intricate plastic molds, but JMT leveraged innovative solutions to overcome them.

Achieving Customer’s Request

The customer needed a lightweight yet durable plastic pallet with strict dimensional tolerances (±0.1mm) and a smooth surface finish. JMT optimized material selection (using PP+20% glass fiber), redesigned rib structures for strength, and added texture to improve grip.

Mold Design

Key innovations:

Parting line optimization to eliminate flash.

Conformal cooling channels for faster cycle times.

Modular inserts for easy maintenance.

Mold Flow Analysis

Simulations predicted sink marks near ribs. JMT adjusted gate locations and added overflow zones, reducing defects by 90% before tooling.

Mold Machining

JMT used 5-axis CNC for core/cavity machining and EDM for precise slider mechanisms. Total machining accuracy: ±0.02mm.

Quality Control

CMM verified critical dimensions. Trial runs included 500-shot tests with weight monitoring (±2g tolerance).

Conclusion

JMT delivered the mold 10% faster than industry benchmarks. We turn complexity into reliability.

| The Company | Taizhou Huangyan JMT Mould CO.,LTD |

| The contact | jennifer |

| The Address | |

| The Website | https://wmmworld.co/com/jmtmould/ |

Response Rate: High

Avg Response Time: 24–48 h

Business Type:Manufacturers , Traders