BL2020 CNC Angle Steel PUNCHING Hole Cutting Machine

FIN CNC Machine

iron tower manufacturing, steel structure manufacturing, wind power station manufacturing, bridge/railway manufacturing, truck manufacturing

iron tower manufacturing, steel structure manufacturing, wind power station manufacturing, bridge/railway manufacturing, truck manufacturing

The machine is mainly work for making angle steel components in the iron tower industry.

It can complete marking, punching and fixed-length cutting on the angle steel.

Simple operation and high production efficiency.

Details And Advantages

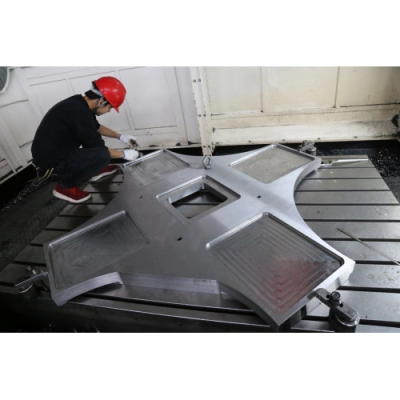

1、The main structure is composed of a marking unit, two punching units and a shearing unit.

(1) The marking unit adopts a closed body, which is very strong. With four interchangeable prefix boxes, each

The prefix box can hold 10 characters;

(2) The punching unit adopts a closed body, which is very strong and can be installed on the closed bed

Full-length material support and pressing device can ensure accurate distance. Each punching unit is equipped with

Three die sets to punch three different diameter holes on each side of the angle.

The transmission changes the quasi-distance, and the quasi-distance is steplessly adjusted.

(3) The shearing unit adopts a closed body, which is very strong. Double-blade shearing mechanism ensures cutting

The surface is neat and the shear gap is easy to adjust. The single blade cutting mechanism ensures that the cutting section is neat and the shearing clearance is easy to adjust.

2、The angle steel is clamped by pneumatic clamps and moves quickly for positioning. X-axis feeding adopts servo motor

Transmission, rotary encoder feedback, full closed-loop control, high precision.

3、 The transverse fore hearth is composed of four chains with dials and a frame body. The chains are decelerated by the motor

machine driven.

4、The rotary feeder is driven by the motor through the reducer and the chain, and rotates the angle steel on the horizontal in-feeding material conveyor into the longitudinal conveyor.

5、The discharge material channel is composed of material channel body and cylinder. The finished angle steel is thrown out of the production line by its rotation after coming out of the main machine part.

6、 The machine has three CNC axes: The movement and positioning of the feeding trolley, and the up and down movement and positioning of the die frame of the punching unit.

7、The air cylinder, solenoid valve, hydraulic valve, PLC programmable controller, servo motor, driver, etc. configured by the machine are imported parts, which are of high quality and ensure the high reliability and high precision of the equipment.

8、The computer programming is easy, and it can display the material graphics and the coordinate size of the hole position, which is convenient for inspection. The use of upper computer management greatly facilitates the storage and calling of programs; the display of graphics; fault diagnosis and remote communication.

| The Company | FIN CNC Machine |

| The contact | FinCM |

| The Address | |

| The Website | https://wmmworld.co/com/fincm/ |

BL2020 CNC Angle Steel PUNCHING Hole Cutting Machine

Response Rate: High

Avg Response Time: 24–48 h

Business Type:Manufacturers , Traders