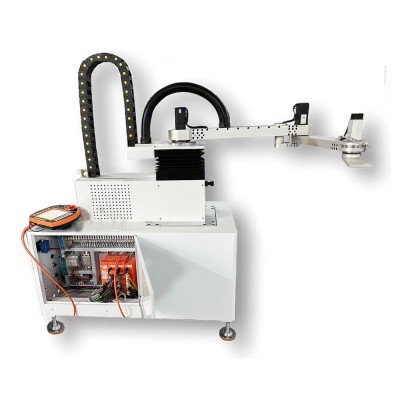

Horizontal Dual-spindle CNC Deep Hole Drilling Machine

FIN CNC Machine

iron tower manufacturing, steel structure manufacturing, wind power station manufacturing, bridge/railway manufacturing, truck manufacturing

iron tower manufacturing, steel structure manufacturing, wind power station manufacturing, bridge/railway manufacturing, truck manufacturing

The machine is mainly used for petroleum, chemical, pharmaceutical, thermal power station, nuclear power station and other industries.

The main function is drilling holes on the tube plate of the shell and tube sheet of heat exchanger.

The maximum diameter of the tube sheet material is 2500(4000)mm and the maximum drilling depth is up to 750(800)mm.

Details and advantages

1. This machine belongs to horizontal deep hole drilling machine. The precision of the casting bed is stable, on which there is a longitudinal sliding table, which works to carry the column for longitudinal (X-direction) movement; the column is equipped with a vertical sliding table, which carries the spindle feed sliding table for vertical (Y-direction) movement; the spindle feed sliding table drives the spindle for feed (Z-direction) movement.

2. The X, Y and Z axis of the machine are all guided by linear roller guide pairs, which has extremely high bearing capacity and superior dynamic response performance, no gap and high motion accuracy.

3. The worktable of the machine is separated from the bed, so that the clamped material will not be affected by the vibration of the bed. The worktable is made from cast iron with stable precision.

4. The machine has two spindles, which can work at the same time. The efficiency of the machine is nearly double that of the single spindle machine.

5. The machine is equipped with a flat chain type automatic chip remover. The iron chips generated by the drilling tool are sent to the chain type chip remover through the chip removal conveyor, and the chip removal works automatically.

6. The machine is equipped with automatic lubrication system, which can regularly lubricate the parts to be lubricated such as guide rail and screw, effectively ensuring the stable operation of the machine and improving the service life of each part.

7. Simens828D/ FAGOR8055 numerical control system is adopted in the machine numerical control system, which is equipped with electronic hand wheel, so it is convenient for operation and maintenance.

| The Company | FIN CNC Machine |

| The contact | FinCM |

| The Address | |

| The Website | https://wmmworld.co/com/fincm/ |

Horizontal Dual-spindle CNC Deep Hole Drilling Machine

Response Rate: High

Avg Response Time: 24–48 h

Business Type:Manufacturers , Traders